Fitur Mesin

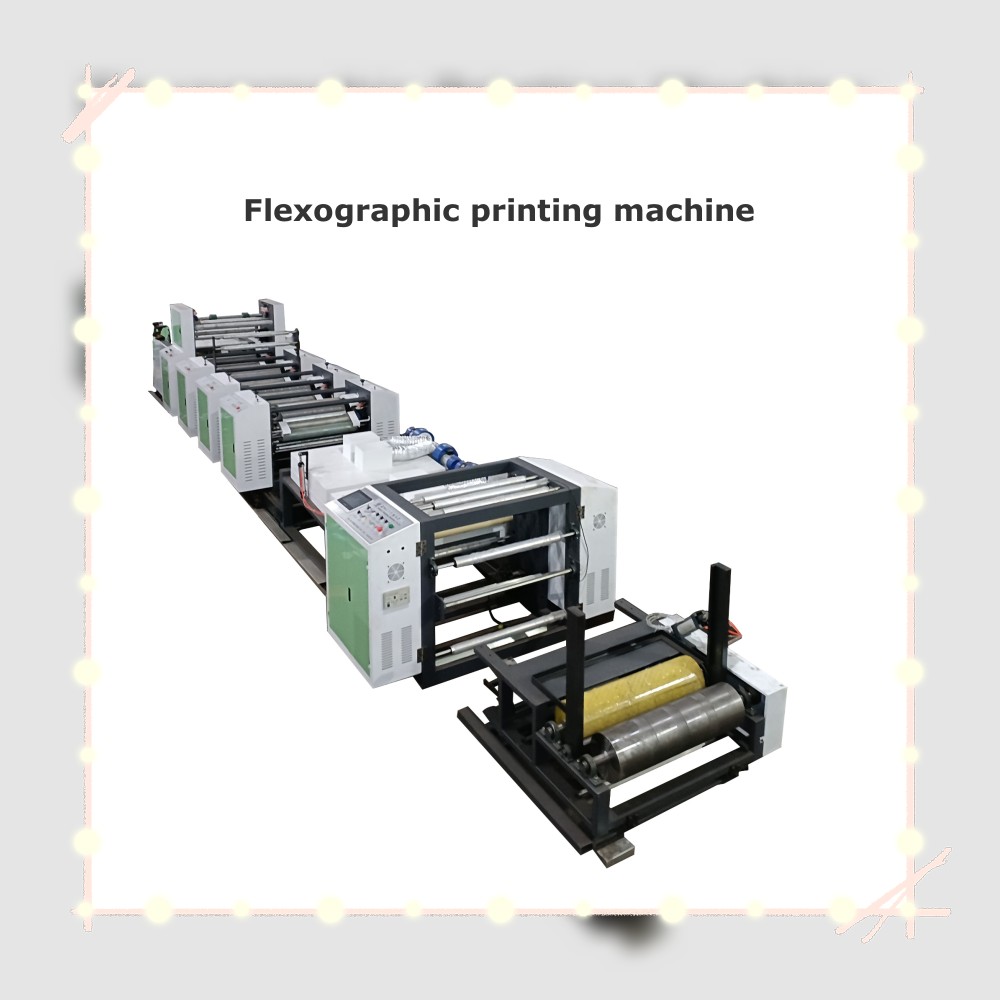

The production process of this unit: Put the compounded woven roll cloth on the unloading frame, pass through the deviation correction frame, and enter the printing area with the floating roller frame in the storage area, and pre-stick the flexible board surface. The printing length is controlled by the servo control system. After printing, the printed bag is sent to the winding section by the floating pressure roller, and then the whole roll is wound by the winding machine until the finished product is printed and enters the subsequent slitting process.

The new feature of this equipment: the servo electric system controls the printing length, and the whole roll printing saves the labor quantity. Advanced programming system improves production efficiency.

Parameter Mesin

| Model | MS-800 |

| Printing bag length(MM) | 300-3000mm |

| Printing bag width(MM) | 300-800mm |

| Kapasitas produksi | 40-120Pcs/min |

| Power supply | 380V 50Hz |

| Kekuatan total | 20KW |

| Weight | 4000kg |