Machine’s Feature

- Full automatic

- Easy operation

- High production efficiency

- Application on Woven bag, OPP bag, Laminated Bag etc.

Tips: Due to machine’s upgrade, machine’s configuration, colors, surface may different, supplier keep the rights to modify.

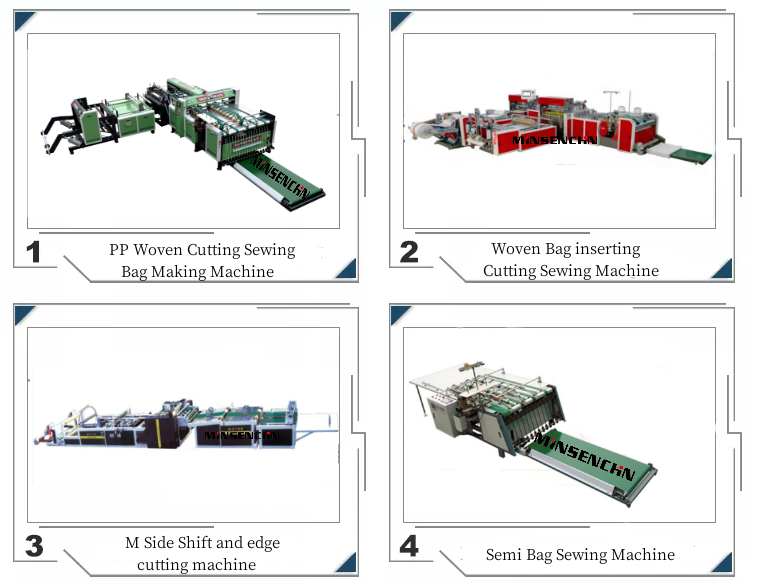

Inner Bag Machine

you can insert the following

- LDPE

- LLDPE

- HDPE

that might be needed based on your needs. It creates stronger and tighter packaging, especially for finer granule products.

Machine's Parameter

| Fabric roll (outer woven bag) width (mm) | 350 - 750 |

| PE film (inner bag) than outer bag width (mm) | +20 |

| PE film thickness (mm) | ≥0.01 |

| Outer woven bag cutting length (mm) | 600 - 1200 |

| Cutting accuracy (mm) | ± 1.5 |

| Needle distance (mm) | 7.0 -12 |

| Speed(pcs/min) | 26 - 32 |

| printing plate thickness(mm) | 3.8 |

| Printing ink | water/oily |

| Voltage | 3 phase 380/220 |

| Power (KW) | 16.5+8 |

| Air pressure(MPA) | ≥ 0.8 |

| Main Head Size(mm) | 5300*1900*1500 |

| Un-winding Unit Size(mm) | 1960*1400*1200 |

| Dimensions of PE film unwinder(mm) | 1340*1120*1400 |

| Dimensions of the printing machine(mm) | 7000*1400*1300 |

| Dimensions of bag closing machine(mm) | 1500*1250*200 |

| Overall weight (T) | 3.8+1.5 |